CWI Services, LLC

We specialize in welding inspection and nondestructive testing (NDT) services for contractors and welding professionals. Our certified inspectors help ensure weld quality, safety, and compliance with AWS and industry codes.

Our Services

Welding Inspection & Third-Party NDT Services

API • AWS • ASME Code Compliance

We provide professional welding inspection and third-party NDT services supporting API, AWS, and ASME code compliance for industrial, infrastructure, and government-funded projects. Our inspection services focus on weld quality, safety, and regulatory compliance while minimizing risk, rework, and project delays.

On-Site Welding Inspection

On-site welding inspections are performed at fabrication shops and job sites to verify compliance with approved Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), material traceability, joint fit-up, preheat and interpass temperature control, and post-weld heat treatment requirements. All inspections are conducted in accordance with applicable API, AWS, and ASME codes.

Visual Testing (VT)

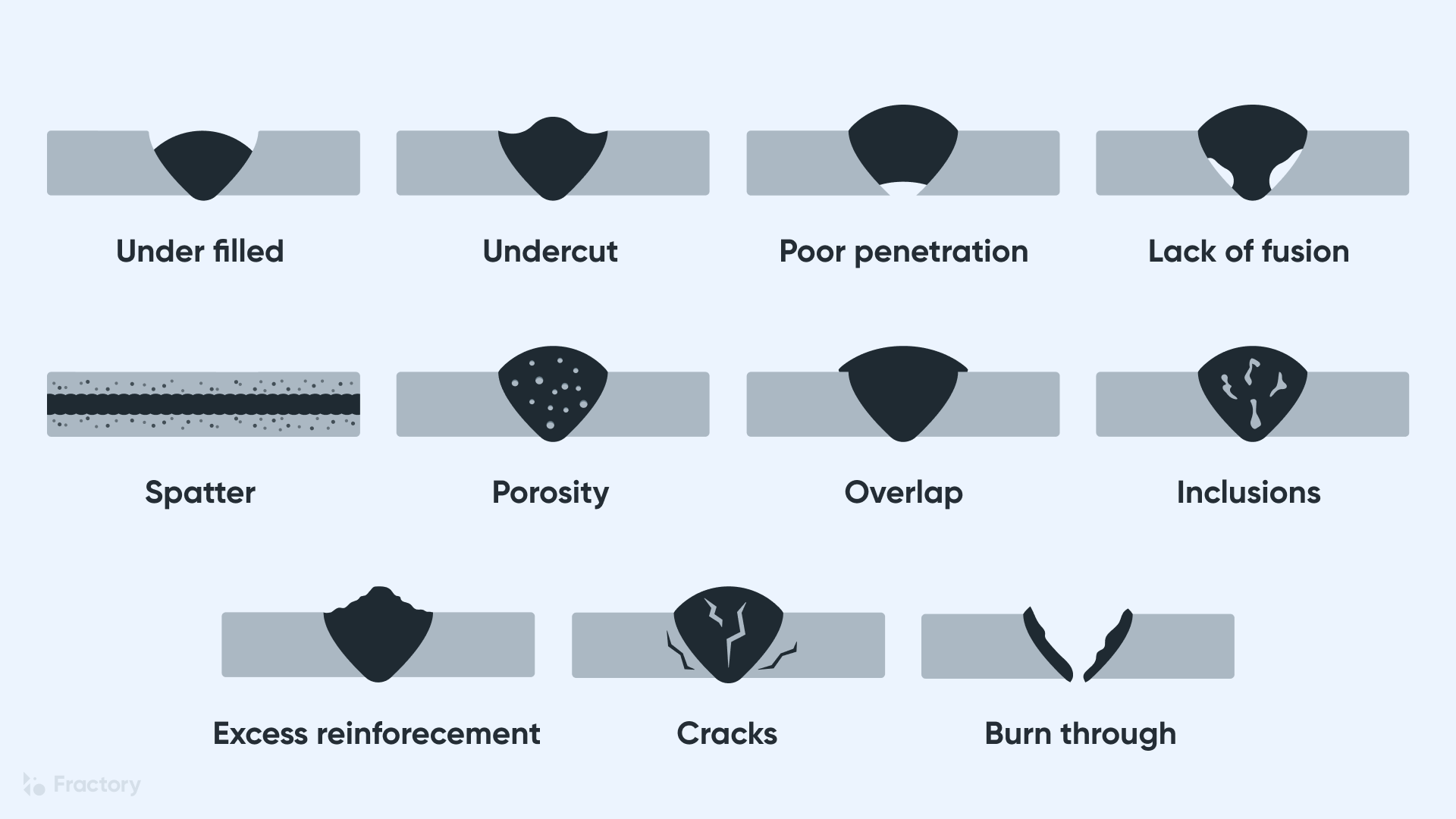

Visual Testing (VT) is a primary non-destructive testing (NDT) method used to evaluate weld quality and workmanship. VT inspections identify surface discontinuities such as cracks, porosity, undercut, overlap, and incomplete fusion in accordance with applicable AWS, ASME, and API acceptance criteria.

Dye Penetrant Testing (PT)

Dye Penetrant Testing (PT) is a non-destructive examination method used to detect surface-breaking defects in welds and base materials. PT is performed in accordance with applicable AWS and ASME standards and is effective for identifying fine cracks, laps, and porosity not detectable by visual inspection alone.

Quality Assurance & Quality Control (QA/QC)

Our QA/QC services support consistent weld quality and full compliance with project specifications and governing codes. QA/QC activities include review and verification of WPS and PQR documentation, welder qualifications, material certifications, inspection and test plans (ITPs), and NDT records. Structured QA/QC oversight ensures traceability, documentation accuracy, and readiness for audits and regulatory review on API, AWS, ASME, and government-regulated projects.

Independent Third-Party Weld Inspection for Government Contracts

We provide independent third-party welding inspection services for government, municipal, and federally funded projects requiring objective verification of weld quality and code compliance. Our inspections meet API, AWS, and ASME requirements and deliver unbiased reporting, traceability, and documentation required for contract compliance, audits, and regulatory oversight. Third-party inspection reduces liability, increases transparency, and supports successful project execution.

Commercial & Industrial Welding and Fabrication Services

We provide professional welding and fabrication services for commercial and industrial applications, delivering strong, precise, and code-compliant results. Our certified welders specialize in structural welding, custom metal fabrication, and industrial repairs, working with carbon steel, stainless steel, aluminum, and specialty alloys.

From new construction to equipment repair and plant modifications, we support demanding environments with MIG, TIG, and Stick welding performed to AWS, ASME, and project-specific requirements. Our team offers both shop and on-site welding services, ensuring minimal downtime and dependable turnaround.

Trusted by commercial contractors and industrial facilities, we deliver reliable workmanship, safety-focused execution, and fabrication solutions built to perform.

I

Welding Procedure Specification (WPS) & Procedure Qualification (PQR) Services

CWI Services, LLC delivers end-to-end welding procedure development, qualification, and code compliance support for fabrication, construction, and industrial projects across the United States. Our certified welding professionals develop technically sound, fully documented welding procedures that meet ASME, AWS, API, and project-specific code requirements, reducing risk, improving weld quality, and accelerating approvals.

Welding Procedure Specification (WPS) Development

We develop custom, code-compliant Welding Procedure Specifications (WPSs) engineered for repeatable, high-quality welds in real-world production environments. Each WPS is built around your materials, joint design, welding process, and service conditions.

Our WPS development includes:

Welding process selection (SMAW, GTAW, GMAW, FCAW, SAW, etc.)

Base material and filler metal compatibility

Joint design, welding positions, and progression

Electrical parameters (amperage, voltage, travel speed)

Shielding gas composition and flow rates

Preheat, interpass temperature, and post-weld heat treatment (PWHT)

Essential, supplementary essential, and nonessential variables per applicable code

All WPS documents are prepared to comply with ASME Section IX, AWS D1.1/D1.5/D1.6, API 1104, and other governing standards as required.

WPS Writing & Technical Documentation

Clear documentation is critical to fabrication success. Our team produces professionally written, audit-ready WPS documentation that is easy for welders to follow and inspectors to verify.

We ensure:

Complete technical detail and traceability

Clear formatting aligned with industry best practices

Full alignment with supporting PQR data

Documentation suitable for client, third-party, or regulatory review

This reduces shop errors, minimizes rework, and supports consistent welder performance.

Procedure Qualification Record (PQR) Development

CWI Services provides full PQR development and oversight, ensuring your welding procedures are properly qualified and defensible under code.

Our PQR services include:

Qualification test planning and variable control

Test coupon preparation and welding supervision

Recording of all required welding parameters

Verification of essential and supplementary essential variables

Compilation of complete PQR documentation

Each PQR validates that the proposed WPS can produce welds with acceptable mechanical and metallurgical properties.

Welding Procedure Qualification Testing

We coordinate and manage destructive and non-destructive testing required for procedure qualification, working with accredited testing laboratories to ensure accurate, code-compliant results.

Testing services include:

Visual inspection (VT)

Mechanical testing (tension, guided bend)

Impact testing (Charpy V-Notch), when required

Additional NDE as specified by code or client requirements

All test results are reviewed and incorporated into final PQR documentation.

Welding Engineering Consultation & Code Compliance Support

Our certified welding inspectors and welding specialists provide expert consultation to support challenging applications and compliance concerns.

We assist with:

Code interpretation and applicability

Material selection and weldability analysis

Welding process optimization

Addressing nonconformances and procedure revisions

Owner, engineer, and third-party coordination

Professional Welder Training and Certification Services

CWI Services, LLC provides industry-leading welder training and certification services designed to meet and exceed nationally and internationally recognized welding standards. Our programs are fully aligned with ASME (American Society of Mechanical Engineers), AWS (American Welding Society), and API (American Petroleum Institute) codes and specifications, ensuring compliance across industrial, structural, pressure vessel, and pipeline applications.

Our comprehensive approach combines technical instruction, hands-on welding performance qualification, and formal certification testing to support workforce development, regulatory compliance, and quality assurance.

Core Welder Training & Certification Services

Code-Compliant Welder Training Programs

We deliver structured theoretical and practical welding instruction in accordance with ASME Section IX, AWS D1.x codes, and applicable API standards. Training is customized to specific processes, materials, and code requirements.

Certification Exam Preparation & Testing

Our certification preparation programs ensure welders are fully qualified and test-ready. Performance Qualification Tests (PQR/WPQ) and written examinations are administered in strict compliance with governing codes and acceptance criteria.

Certified Welding Instructors & Inspectors

All training and testing are conducted by experienced professionals holding active credentials in ASME, AWS, and API. Our instructors bring real-world field experience to every training environment.

On-Site and Off-Site Welding Training Solutions

CWI Services, LLC offers flexible training delivery options, including on-site welding training at client facilities, off-site training centers, and remote classroom instruction for theory-based modules.

Nationally Recognized Welding Certifications

Certification testing is performed in accordance with applicable industry standards, resulting in official welder certifications recognized nationwide across fabrication, construction, energy, and manufacturing sectors.

Welding Certification Services for Educational Institutions

CWI Services, LLC partners with technical schools, community colleges, and vocational training institutions to deliver accredited welding certification services that strengthen program credibility and improve graduate employability.

Educational Certification & Program Support

Industry-Aligned Program Development

We assist institutions in aligning welding curricula with current ASME, AWS, and API certification requirements, ensuring students are trained to real-world industry standards.

On-Site Institutional Certification Testing

CWI Services provides on-campus administration of welder performance qualification tests and certification exams, reducing logistical barriers for students and faculty.

Faculty Certification & Professional Development

We offer instructor training and certification maintenance programs to support faculty compliance, instructional consistency, and continuing education requirements.

Curriculum Enhancement & Training Resources

Institutions receive access to code-compliant instructional materials, welding procedures, and technical documentation aligned with industry best practices.

Compliance, Documentation & Record Management

All certifications, test records, and qualification documentation are maintained in accordance with regulatory and code requirements to support audits and accreditation reviews.

Why Choose CWI Services, LLC

By partnering with CWI Services, LLC, welders, employers, and educational institutions gain access to trusted expertise in welding training, inspection, and certification. Our technical precision, code knowledge, and commitment to quality help clients maintain compliance, improve weld quality, and remain competitive in today’s highly regulated industrial environment.

Equipment Selection Services

We provide expert and detailed guidance to help you carefully choose the most appropriate welding equipment tailored specifically to your unique project requirements, ensuring maximum operational efficiency and superior product quality.

Consumable Waste Management

Our dedicated team offers effective strategies designed to minimize consumable waste, significantly reducing costs and lessening environmental impact while consistently maintaining optimal welding performance and reliability.

Welding Issue Troubleshooting

We promptly diagnose and resolve a wide range of welding problems, from material defects to process inconsistencies, helping you maintain seamless operations and consistently deliver high-quality end results.

Technical Support

Access our comprehensive technical assistance for all welding-related inquiries, including process optimization, routine equipment maintenance, and material compatibility issues, to effectively support and enhance your ongoing production needs.

About

CWI Services, LLC

CWI Services, LLC was established in 2019 by an AWS Certified Welding Inspector (CWI) with over 20 years of progressive experience in the welding, fabrication, and inspection industries. As a veteran-owned small business, CWI Services, LLC provides professional welding inspection, quality assurance, and code compliance services throughout the United States.

The company’s founder possesses extensive hands-on expertise across structural steel, pipeline, and fabrication projects, complemented by more than a decade of experience as a welding instructor at accredited educational institutions. This combination delivers a comprehensive understanding of welding processes, inspection methodologies, and applicable codes and standards, including AWS D1.1, ASME, and other governing specifications.

By integrating real-world field experience with advanced technical knowledge and formal instruction, CWI Services, LLC delivers accurate, defensible, and standards-compliant inspection services. The company is committed to maintaining the highest levels of quality control, safety, and professionalism, helping clients nationwide meet regulatory requirements, reduce risk, and ensure long-term project integr